Your car’s engine is secured to the frame by several mounts that are designed to keep it stable while absorbing vibration. These mounts are typically made of metal and rubber, with the rubber acting as a cushion to prevent excessive movement and noise. Like many parts on a vehicle, engine mounts are not meant to last forever. Over time, they can wear down, crack, or even collapse completely.

Knowing what leads to engine mount failure can help you stay ahead of problems before they become serious.

Natural Wear and Age

Even under normal driving conditions, engine mounts wear out with time. The constant exposure to heat, engine vibration, and general stress causes the rubber to harden and lose flexibility. As the material breaks down, it becomes more prone to cracking or separation.

Vehicles that are 7 to 10 years old or have passed 100,000 kilometers are more likely to show signs of mount fatigue, though it can happen sooner depending on driving habits.

Heat and Oil Exposure

Heat is one of the biggest enemies of rubber. In the engine bay, temperatures often reach levels that slowly deteriorate rubber components. When rubber mounts are constantly exposed to high heat, they become brittle and start to crack.

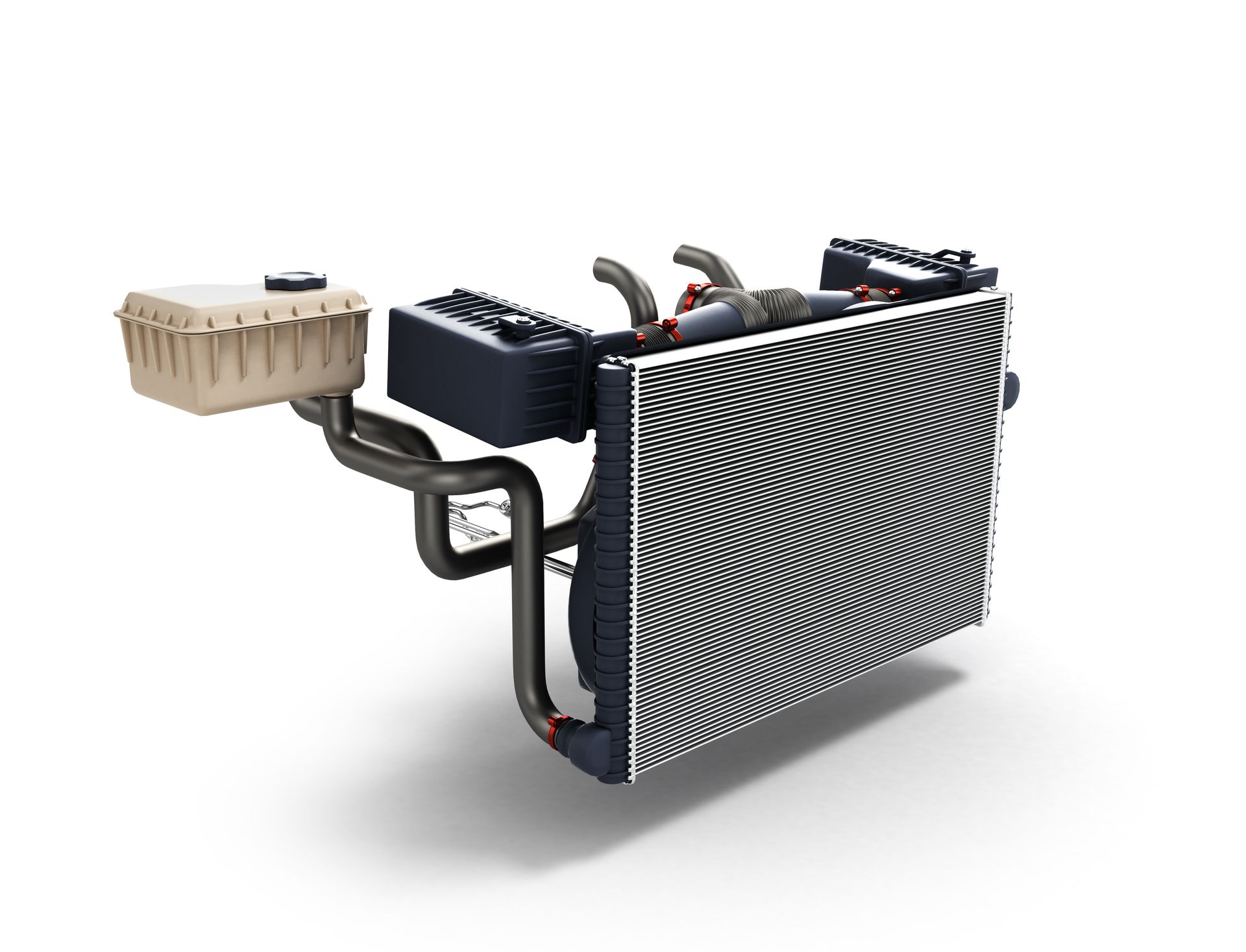

Oil and transmission fluid leaks make the problem worse. These fluids can soften rubber and speed up the breakdown process. Even a small leak that is left unaddressed can cause a mount to fail prematurely.

Rough Driving Habits

Driving aggressively, accelerating hard, or braking suddenly puts extra strain on engine mounts. So does driving on rough roads, where the suspension and engine are constantly jostled. Over time, these stresses wear the mounts down faster.

Vehicles used for towing or carrying heavy loads are also more likely to suffer from early mount failure due to the additional force applied during operation.

Poor Installation or Low-Quality Parts

Not all replacement mounts are created equal. If a previous mount was replaced using low-quality aftermarket parts, it may not last as long. Similarly, improper installation can put extra stress on the mount, leading it to wear unevenly or fail earlier than expected.

That’s why it’s important to use parts that meet the manufacturer’s standards and have them installed by an experienced technician.

Signs Your Engine Mounts May Be Failing

As mounts begin to crack or collapse, the symptoms often start small but grow more noticeable:

- Unusual vibration inside the cabin, especially at idle

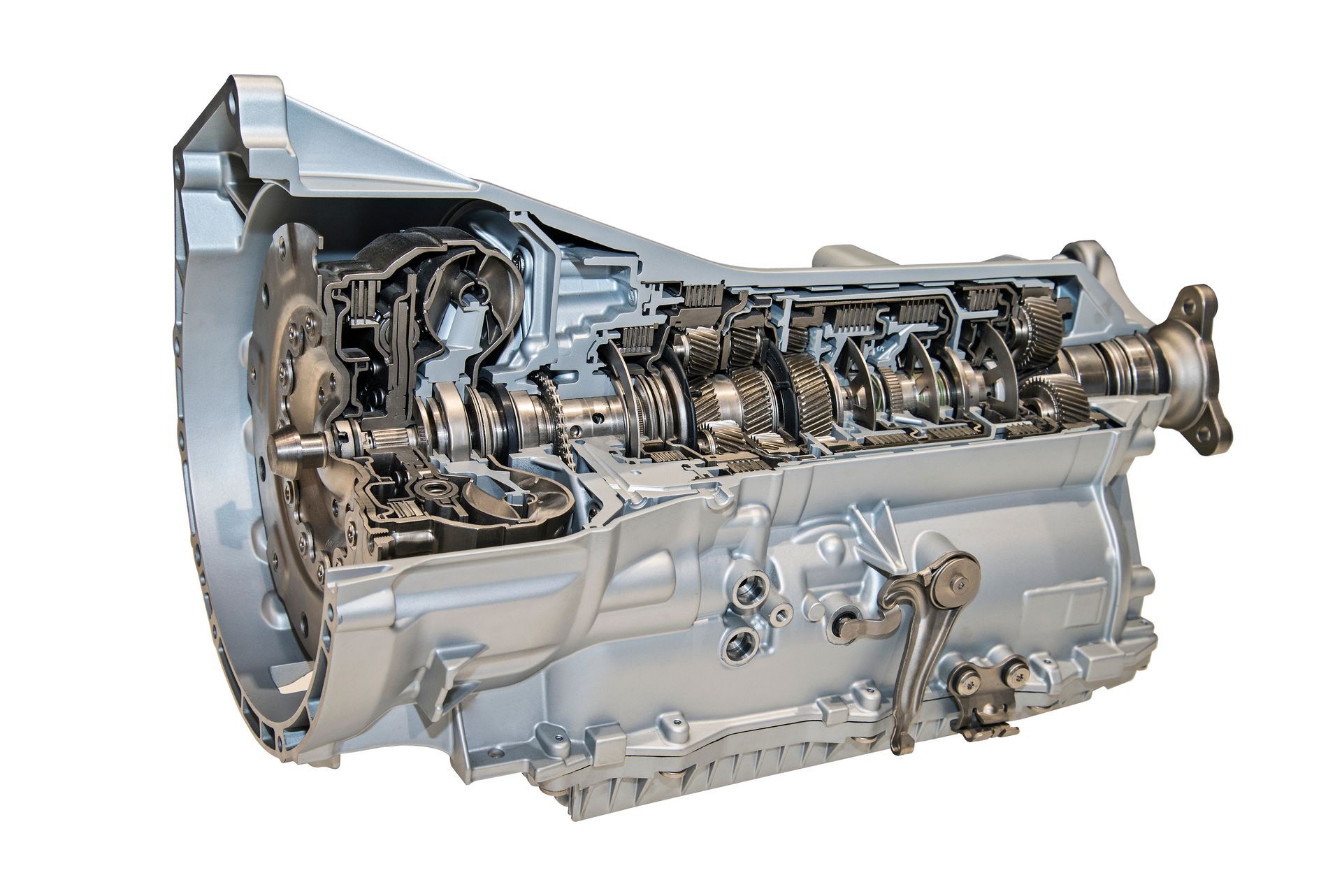

- A clunking sound when accelerating or shifting gears

- Visible engine movement when the hood is open

- Misalignment between the engine and connected components

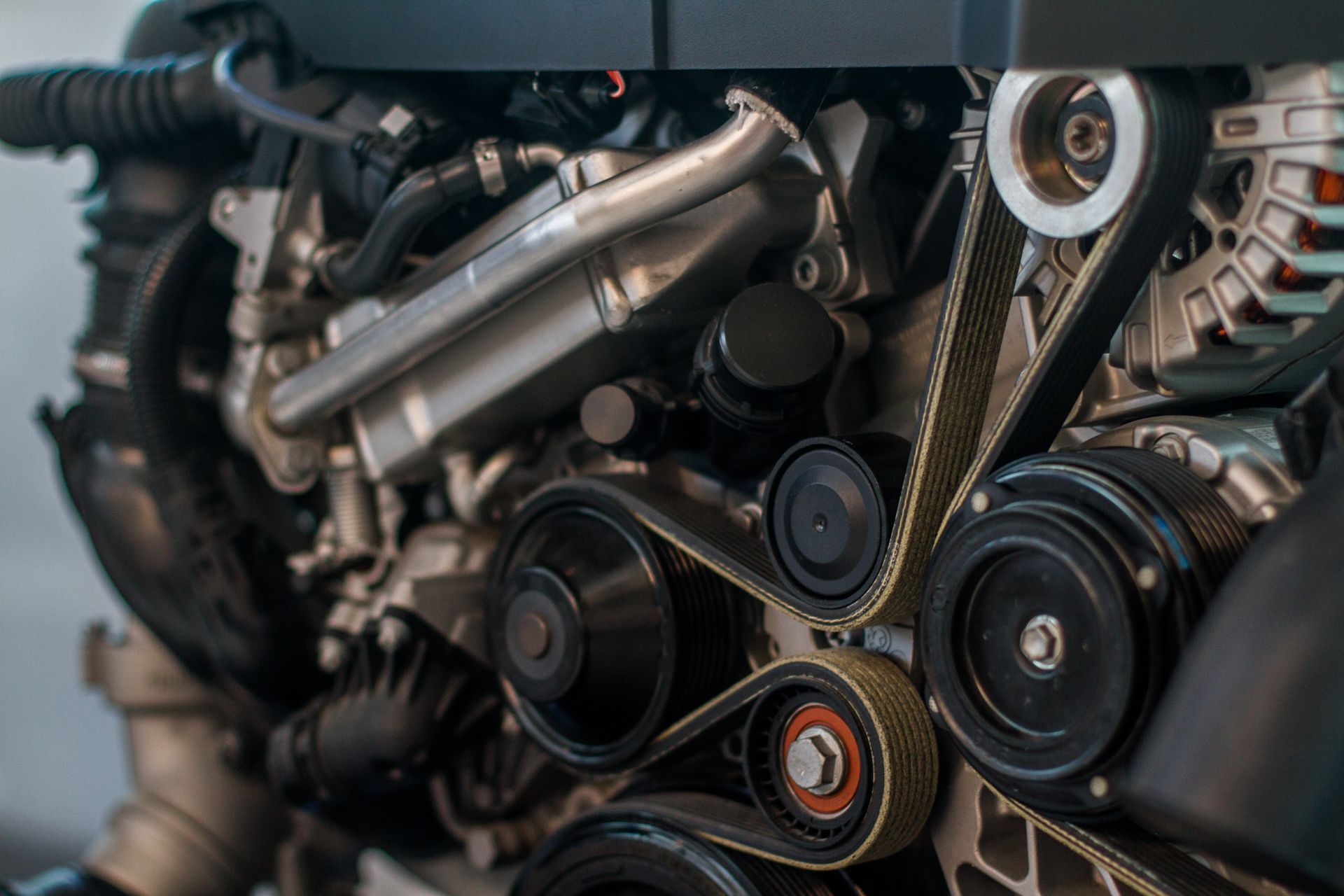

- Damage to surrounding hoses, belts, or wiring

If any of these signs appear, it’s a good idea to have the mounts inspected before they cause further problems.

What Happens If You Ignore Damaged or Worn-Out Mounts

A damaged engine mount may not stop your car from running, but it can lead to a rough ride, higher repair costs, and added wear on other components. As the engine shifts under load, it can place stress on exhaust connections, cooling hoses, and electrical wiring. In rare cases, a broken mount can even cause drivetrain misalignment or contribute to axle or transmission damage.

Replacing mounts when they first show signs of failure is much cheaper than waiting until other parts are affected.

Engine Mount Inspections and Replacement at Silvhorn Automotive in Pemberton, BC

At Silvhorn Automotive, we understand how a worn or broken mount can affect your entire vehicle. Our technicians can inspect your engine mounts, check for damage, and recommend a reliable replacement when needed. Whether you’re dealing with extra vibration, clunking sounds, or just suspect something isn’t quite right under the hood, we’re here to help.

Book an appointment with

Silvhorn Automotive in Pemberton today and let us keep your engine running securely and smoothly.